Yo, what’s up, squad! Ready to dive into the world of foam laser cutting? Buckle up ’cause we’re about to embark on a rad journey through the realms of crafting and industry, where foam laser cutting reigns supreme!

But why is foam laser cutting such a big deal? Well, lemme tell ya, it’s not just about making clean cuts. Nah, it’s about revolutionizing the way we craft and manufacture stuff. Think about it – from intricate designs to precise shapes, foam laser cutting opens up a whole new world of possibilities. It’s like unleashing your creativity on steroids!

So, buckle up, fam, ’cause we’re about to dive deep into the world of foam laser cutting, where precision meets passion and crafting reaches a whole new level of lit-ness! Let’s do this! 🚀

What’s the Buzz About Foam Laser Cutting?

Alright, listen up, fam! It’s time to spill the tea on why foam laser cutting has got everyone buzzing like a beehive at Coachella. Trust me, this ain’t just some regular cutting technique – it’s the real deal, and here’s why it’s sending shockwaves through the crafting and industrial scenes.

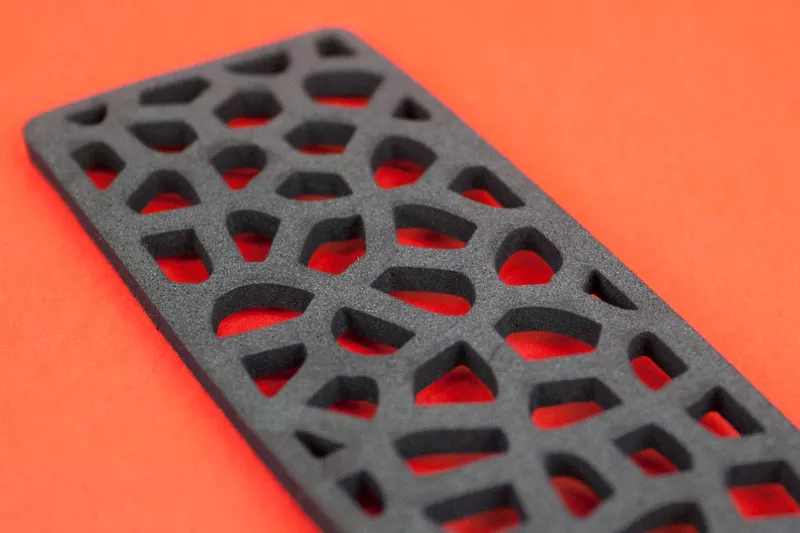

First off, let’s talk about versatility, ’cause foam laser cutting is like the Swiss Army knife of cutting methods. You wanna slice through foam materials like they’re hot? Boom, foam laser cutting’s got your back! It’s versatile AF, meaning you can cut through foam of all shapes, sizes, and thicknesses with the precision of a surgeon. Say goodbye to wonky cuts and hello to perfection!

- Precision like never before

- Versatility for endless possibilities

- Revolutionizing crafting and industry

- Applications in packaging, signage, and more

- Taking creativity to new heights

But wait, there’s more! We’re talking precision here, people – laser-sharp precision! Foam laser cutting ain’t about leaving rough edges or jagged lines behind. Nah, it’s about delivering cuts so clean, they make your grandma’s kitchen knives look dull. Whether you’re crafting intricate designs or cutting out basic shapes, foam laser cutting nails it every single time.

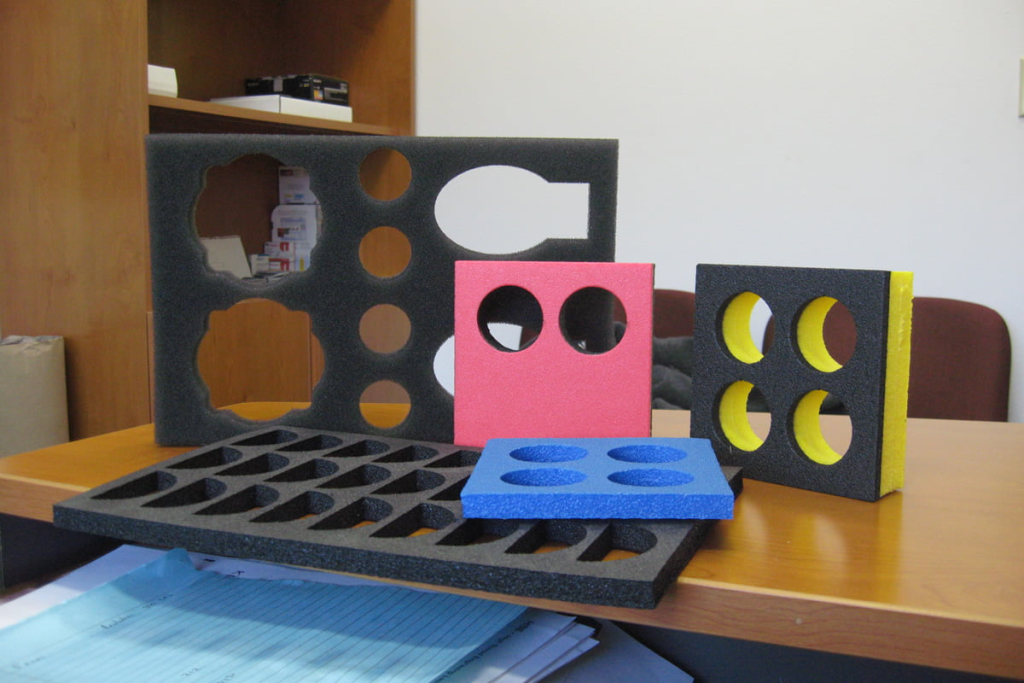

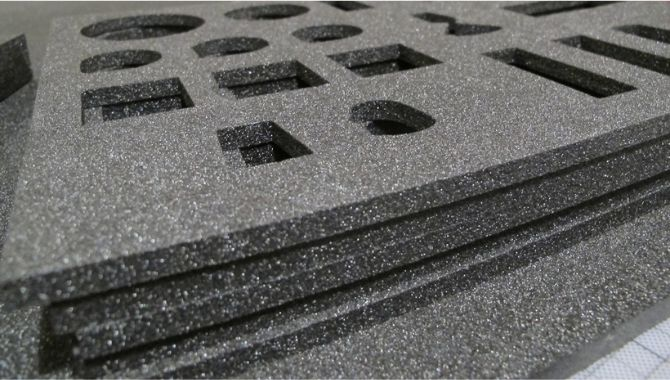

Now, let’s talk applications, ’cause foam laser cutting ain’t just for show – it’s got serious game in the real world too. Picture this: you need packaging that’s as sleek as a Tesla, signage that grabs attention like a viral TikTok, or prototypes that are as flawless as your Instagram selfies. Well, guess what? Foam laser cutting’s got your back, fam! From packaging to signage to prototyping and beyond, this cutting-edge technology is making waves across industries like never before.

So, there you have it, peeps – the lowdown on why foam laser cutting is the hottest thing since sliced bread. It’s versatile, precise, and it’s taking over industries faster than you can say “laser beams.” So, buckle up and hop on the foam laser cutting hype train – ’cause this ride’s about to get lit! 🚀

How Does It Work, Anyway?

Alright, fam, let’s break it down – how the heck does foam laser cutting even work? Well, grab your snacks and buckle up ’cause we’re about to take a deep dive into the world of laser beams and foam materials.

So, picture this: you’ve got your foam material, right? Could be EPS foam, XPS foam, or whatever floats your boat. Now, you wanna cut through it like a hot knife through butter. Enter stage left: laser technology! This ain’t your grandma’s cutting method – oh no, it’s straight outta sci-fi land!

- Laser beam zaps through foam materials

- Surgical precision with sci-fi technology

- Clean, crisp cuts every time

- Different foam materials suitable for cutting

- Like magic, but cooler!

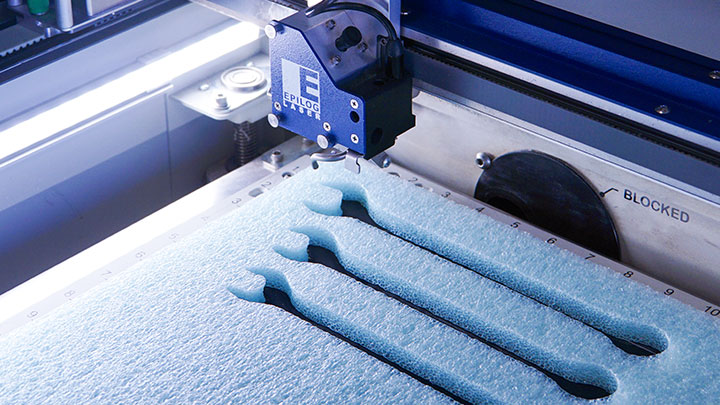

Here’s the deal: foam laser cutting works by using, you guessed it, a laser beam to zap through foam materials with surgical precision. It’s like playing a video game, but instead of wielding a controller, you’re controlling a freaking laser beam! Talk about leveling up, am I right?

Now, let’s talk about the real MVP here – laser technology. Without it, foam laser cutting would be about as effective as trying to cut a steak with a spoon. Laser beams are like the superheroes of precision cutting, able to slice through foam materials with the accuracy of a sniper. Whether you’re cutting intricate patterns or basic shapes, lasers got your back, fam.

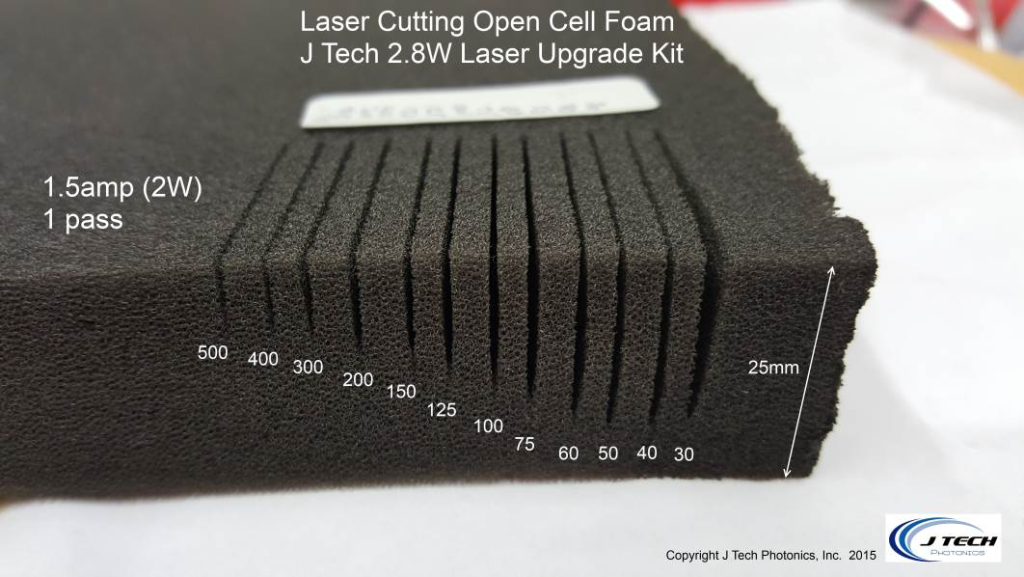

But hold up, not all foam materials are created equal. You’ve got your EPS foam, which is lightweight and perfect for crafting projects. Then there’s XPS foam, which is more dense and suitable for industrial applications. And let’s not forget about PU foam, which is soft and squishy – perfect for cushioning and upholstery.

So, there you have it – the lowdown on how foam laser cutting works. It’s all about harnessing the power of laser beams to slice through foam materials like a boss. So, next time you’re crafting or manufacturing something out of foam, remember: lasers are your best friend! 🚀

Why Foam Laser Cutting Machines Are Lit AF

Yo, listen up, squad! Let’s talk about why foam laser cutting machines are straight-up lit AF. These bad boys ain’t your grandma’s cutting tools – oh no, they’re the Ferrari of foam cutting, and here’s why.

First off, let’s dive into the features, ’cause these machines are packing some serious heat. We’re talking about precision like you’ve never seen before. These babies can cut through foam materials with the accuracy of a ninja throwing stars. No more sloppy cuts or jagged edges – it’s all about clean, crisp lines every single time.

But hold up, it’s not just about precision – speed is the name of the game too. Foam laser cutting machines are faster than a cheetah on Red Bull. Whether you’re cutting out a simple shape or a complex design, these machines get the job done in record time. Say goodbye to long hours spent hunched over a cutting table – with foam laser cutting machines, you’ll be done before you can say “supercalifragilisticexpialidocious.”

- Precision cutting like a ninja

- Speed faster than a cheetah on Red Bull

- Customization options for days

- User-friendly interface for easy operation

- Making waves across industries

And let’s not forget about customization, ’cause these machines are all about giving you the freedom to create. Want to add your own personal touch to your foam creations? No problemo! Foam laser cutting machines let you customize your cuts with ease, whether you’re adding intricate details or funky patterns. It’s like having your own personal laser-powered artist at your beck and call.

But wait, it gets even better – these machines are so user-friendly, even your grandma could use ’em! With a simple interface and intuitive controls, you’ll be cutting foam like a pro in no time. No need for a PhD in engineering – just fire up the machine, load up your design, and let the magic happen.

So, there you have it, fam – the lowdown on why foam laser cutting machines are the bomb dot com. They’re fast, precise, customizable, and easy to use – what more could you ask for? So, if you’re serious about your foam crafting game, it’s time to level up with a foam laser cutting machine. Trust me, you won’t regret it! 🚀

Getting Your Hands on a Foam Laser Cutting Machine

Yo, what’s poppin’, peeps? Ready to get your hands on the hottest piece of tech in town – a foam laser cutting machine? Well, strap yourselves in ’cause we’re about to dive deep into the wild world of foam laser cutting machines and how you can snag one for yourself.

First things first, let’s talk about what’s out there in the market. It’s like a candy store, but instead of candy, you’ve got a smorgasbord of foam laser cutting machines to choose from. Whether you’re looking for something sleek and compact or big and beefy, there’s a machine out there with your name on it. And let me tell ya, the options are endless!

- Exploring the market for options

- Different models, sizes, and price ranges

- Finding the perfect fit for your needs

- Tips for savvy shopping

- Leveling up your crafting game

Now, let’s talk models, sizes, and price ranges – ’cause let’s face it, we all got different needs and budgets, am I right? From entry-level models that won’t break the bank to top-of-the-line machines that’ll have you drooling, there’s something for everyone out there. Want a machine that can handle heavy-duty cutting jobs? You got it. Need something portable that you can take on the go? No problemo. The choice is yours, fam.

So, here’s the deal – do your research, weigh your options, and don’t rush into anything. With a little bit of savvy shopping and some know-how, you’ll be cruising the foam laser cutting game like a pro in no time. So, what are you waiting for? Get out there and snag yourself a foam laser cutting machine that’ll have you cutting foam like a boss! 🚀

Foam Laser Cutting Projects You Need to Try RN

Yo, listen up, fam! It’s time to get your DIY game on fleek with some lit foam laser cutting projects that’ll have you flexing your creative muscles like never before. So grab your foam, fire up that laser cutter, and let’s dive into some seriously dope projects you need to try RN!

First up, we got the ultimate room decor project – custom foam wall art. Whether you’re into minimalist designs or funky patterns, foam laser cutting lets you create wall art that’s as unique as you are. Just fire up your laser cutter, load up your design, and watch as it comes to life right before your eyes. It’s like magic, but cooler!Next, let’s talk about the ultimate accessory – custom foam phone cases. Say goodbye to boring old phone cases and hello to ones that scream “me!” With foam laser cutting, you can create phone cases in any shape, size, or design you can imagine. From funky patterns to personalized initials, the sky’s the limit. Plus, they make great gifts for your squad – talk about squad goals!

- Custom foam wall art for your space

- Personalized phone cases that scream “you”

- Funky foam jewelry to accessorize like a boss

- Step-by-step instructions for beginners

- Unleashing creativity and getting crafty

But hold up, we’re just getting started. How about stepping up your game with some DIY foam jewelry? That’s right, fam – foam laser cutting isn’t just for big projects. You can create some seriously dope jewelry pieces with foam too. From statement earrings to funky necklaces, you’ll be turning heads everywhere you go. And the best part? You can customize them to match your style perfectly.

| Project | Description | Materials Needed | Difficulty Level |

| Custom Wall Art | Create personalized wall decorations | Foam sheets, laser cutter, design software | Beginner-friendly |

| Funky Phone Cases | Design and make custom phone cases | Foam sheets, laser cutter, phone case templates | Intermediate |

| Statement Earrings | Craft unique earrings with foam | Foam sheets, laser cutter, earring hooks | Intermediate |

| 3D Foam Sculptures | Sculpt dimensional foam art pieces | Foam blocks, laser cutter, 3D modeling software | Advanced |

Now, I know what you’re thinking – “But how do I even get started?” Don’t sweat it, fam – I got you covered. Check out these step-by-step instructions for a beginner-friendly foam laser cutting project:

- Choose your design – whether it’s a funky pattern or a simple shape, pick something that speaks to you.

- Prep your foam – make sure it’s clean and flat, with no wrinkles or creases.

- Fire up your laser cutter – adjust the settings to match your foam material and design.

- Load up your design – using the software, load up your chosen design and adjust the size and placement as needed.

- Hit the start button – watch as the laser cutter works its magic, cutting out your design with precision and accuracy.

- Remove your masterpiece – carefully peel away the excess foam to reveal your finished project.

- Admire your handiwork – marvel at your creation and pat yourself on the back for a job well done.